hey guys, bad news, we got only a week to put our robots up in the air

in our Taiwan team, we split to 3 groups, temporarily.

-six college students (MingChuan University)

-two high school students (Justin Kou Ing Lin, Taipei American School / David Huang,

Taipei Municipal Jianguo High School)

-Professional Engineer/teacher(Mr. Chou)

as the whole team, our goal is to send a auto machine to take samples up in the air.

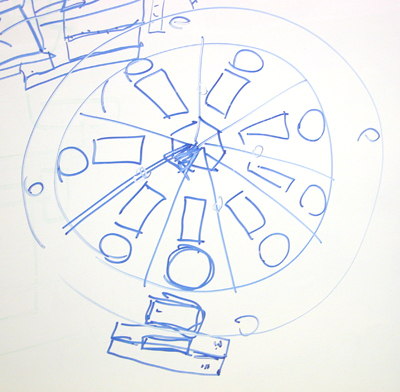

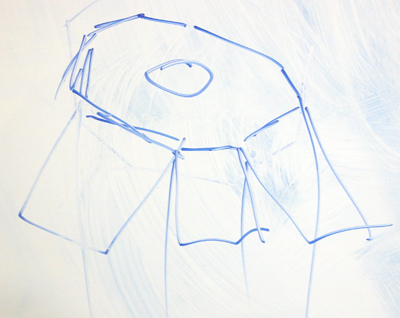

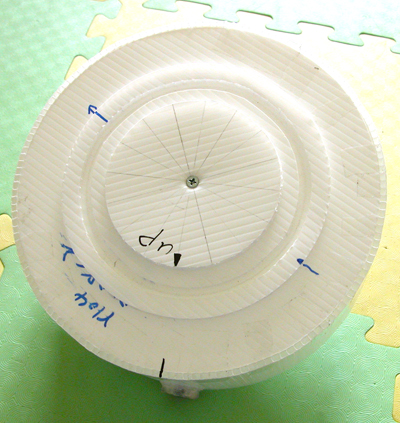

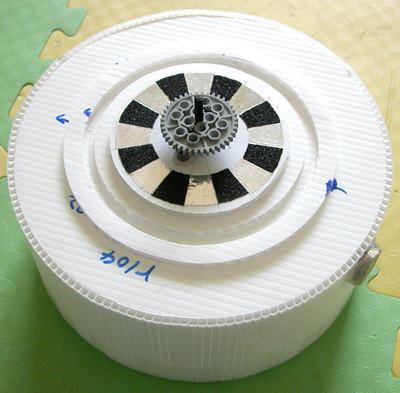

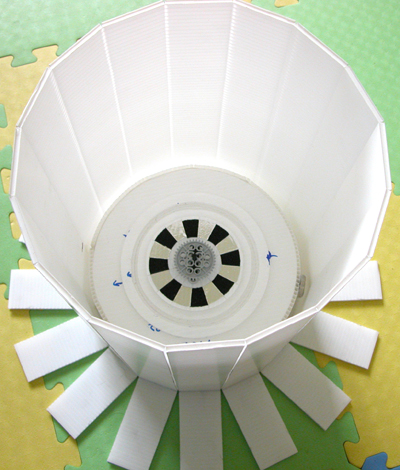

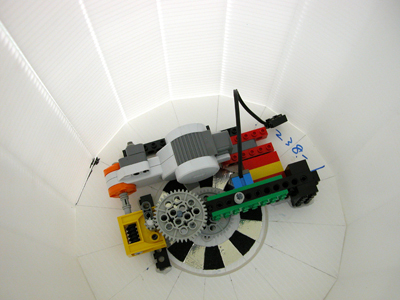

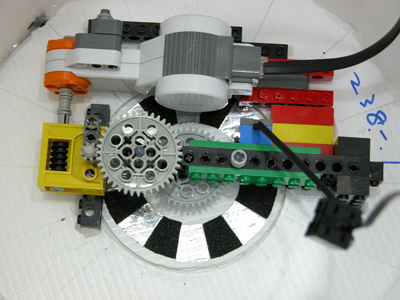

our high school group designed is shown as the picture below

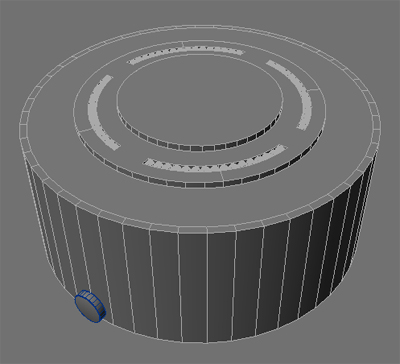

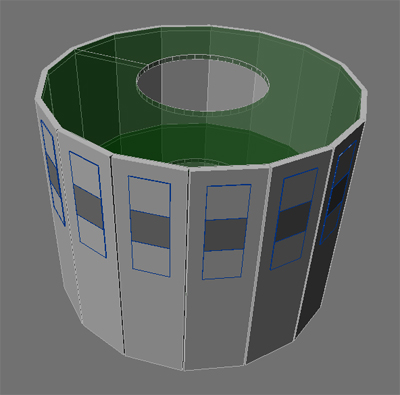

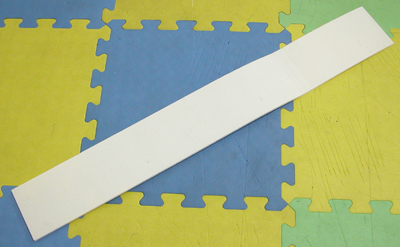

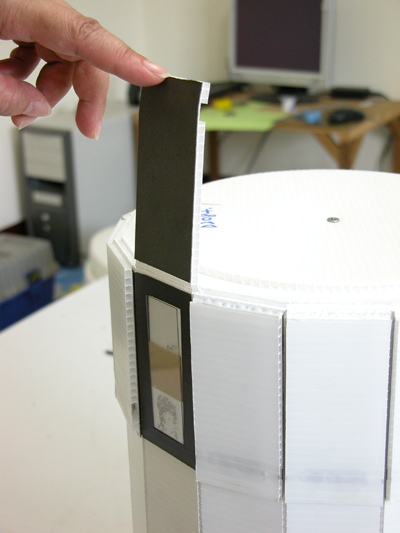

we have two layers of cake styrofoam that is connected by a turning point. the motor in the middle is connected to the top layer, which will be turning the lower layer. We have sixteen individual sealed rooms which each will hold a sample taking tape. There will be a small whole on the outer layer of the cake box so whenever the outer layer is turned to, one out of the sixteen rooms will be exposed to outer air to take sample.

each group from our team has distinctive designs, which we, as a team, will choose the best one to send up in the air.

for our group, the high school team, we faced many challenges. The most obvious challenge for us is the resources and technology we have. Don't even talk about a professional engineer, even college students have their own labs and advance equipments. We only have common tools and our hands. Consequently, we faced inaccurate measurements and incisions.

Secondarily, we need to make sure each individual room is absolutely isolated because we don't want the elements that was taken on each sample to spread throughout the sixteen rooms. there will be no point of making sixteen rooms if that happens. Since the outer layer is turning around the the inner layer of the cake box, there must be some tiny crack at the common boundary connecting the inner layer and outer layer. that tiny crack is enough to let elements from each room to spread around. One of our solution is to use a special material, silica gel. Since the material is flexible, we will use that to be the doors that isolate each room. The silica gel will scrape on the outer layer to make sure each room's dust is kept within it's own space.(the silica gel will be attached on the inner layer.) however, the silica gel will increase the resistance that the motor will have to overwhelm it. we still have to test the motor's strength and find a way to decrease that resistance as much as possible.

Our final task, if every problem above is solved, will be how flinty our compartment should be when it plonks(fails) from 33,000 meters above the ground and all are rooms are still contaminated.

This is a rare and interesting project for us. WISH EVERYONE IN THE TEAM "GOOD LUCK!!"

-Justin Lin